Ball Mills

Home » Ball Mills

Ball Mills

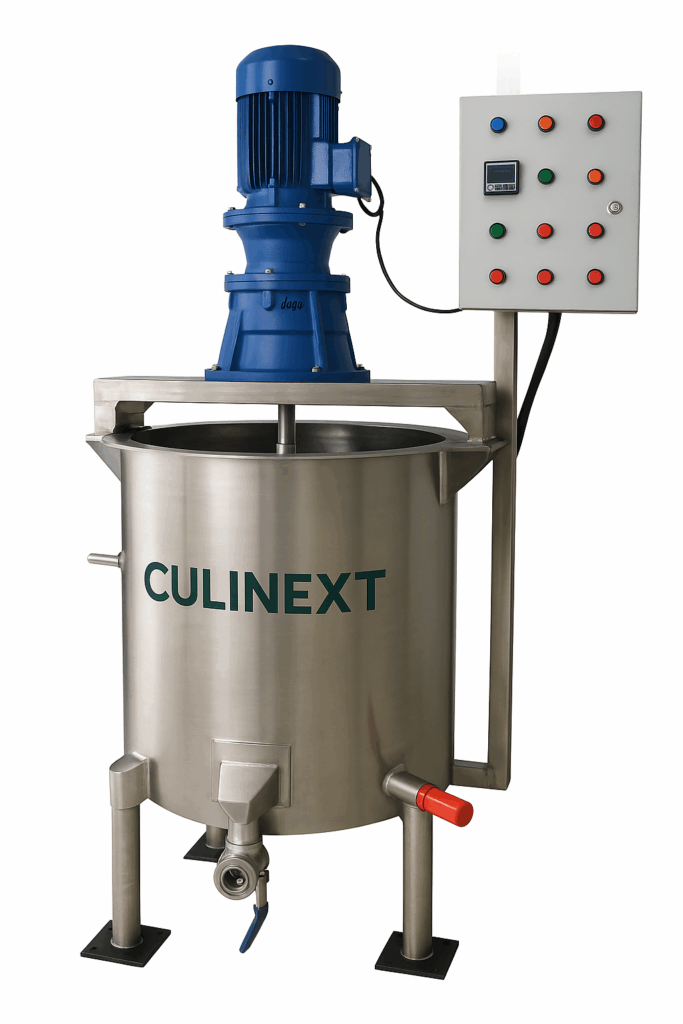

Built for scale, engineered for smoothness — take your chocolate production to the next level.

Usage & Applications

Culinext ball mills are designed for large-scale chocolate refining, giving you silky-smooth consistency at volume.

Commercial chocolate manufacturers

Large-format bakeries and dessert chains

Used By

Private-label chocolate producers

Food factories scaling bean-to-bar lines

Technical Specifications

50kg and 100kg

SS 304 build

Heavy-duty, optimized for long runs

Steel balls for refining cocoa mass and mixtures

Fine grinding and particle reduction for smoother texture

Product Variants

Models in This Category

- 0 / 5

A high-performance vibrating table designed to remove air bubbles, ensure even chocolate distribution, and create a smooth, level finish in molds. Made with a food-grade stainless steel tray and adjustable speed control, it delivers glossy, flawless chocolates with perfect structure and snap ideal for professional confectionery production.

- 0 / 5

A high-performance vibrating table designed to remove air bubbles, ensure even chocolate distribution, and create a smooth, level finish in molds. Made with a food-grade stainless steel tray and adjustable speed control, it delivers glossy, flawless chocolates with perfect structure and snap ideal for professional confectionery production.

- 0 / 5

A high-performance vibrating table designed to remove air bubbles, ensure even chocolate distribution, and create a smooth, level finish in molds. Made with a food-grade stainless steel tray and adjustable speed control, it delivers glossy, flawless chocolates with perfect structure and snap ideal for professional confectionery production.

- 0 / 5

A high-performance vibrating table designed to remove air bubbles, ensure even chocolate distribution, and create a smooth, level finish in molds. Made with a food-grade stainless steel tray and adjustable speed control, it delivers glossy, flawless chocolates with perfect structure and snap ideal for professional confectionery production.

- 0 / 5

A high-performance vibrating table designed to remove air bubbles, ensure even chocolate distribution, and create a smooth, level finish in molds. Made with a food-grade stainless steel tray and adjustable speed control, it delivers glossy, flawless chocolates with perfect structure and snap ideal for professional confectionery production.

- 0 / 5

Introducing our Continuous Chocolate Tempering Machine – the perfect solution for seamless, high-volume chocolate processing. Designed for efficiency and precision, it features a 4 kg bowl capacity ideal for continuous production.

FAQs

Ball mills produce finer chocolate at scale, great for commercial brands needing uniform particle size.

Yes — our machines are built with industrial-grade motors and components.

It depends on the mix and grind level — typically 8–12 hours for optimal results.

Our models support 50kg and 100kg batch sizes — ideal for commercial-scale chocolate production.

Steel balls inside the rotating chamber grind the mixture down to a fine, uniform consistency.

Yes. All parts are sourced locally, ensuring easy support, service, and faster turnaround for any replacements.

- Scale Up

Without Losing Smoothness

Refine your chocolate the professional way — with Culinext ball mills.

Quick Links

Contact Information:

- Aruvi Mobility, Opposite Palakkad ITI West, Kanjikode, Palakkad, Kerala 678623

- +91 70344 40000, +91 73566 79416

- deepak@culinext.co, rithwik@culinext.co

- Monday to Saturday – 9:00 AM to 5:00 PM Closed on Sundays

- Privacy Policy

- Terms of Service