Blogs

- Home

- Blog details

Mastering Chocolate Tempering: Tips for Perfect Results

- By : nitin

Mastering Chocolate Tempering: Tips for Perfect Results

Chocolate is more than just a sweet indulgence—it’s an art form. At Culinext, we believe the foundation of exquisite chocolate creations lies in one essential skill: chocolate tempering. Mastering chocolate tempering ensures that every bar, truffle, or decorative piece has that flawless glossy finish, irresistible snap, and melt-in-the-mouth texture that defines premium quality.

Whether you’re a chocolatier, pastry chef, or a food entrepreneur, this guide will help you perfect the process of tempering chocolate with professional tips and modern automation solutions.

What is Chocolate Tempering?

Chocolate tempering is the process of heating and cooling chocolate to stabilize the cocoa butter crystals. Proper tempering gives chocolate:

-

A shiny, glossy appearance

-

A clean snap when broken

-

A smooth, melt-in-the-mouth texture

-

Resistance to blooming (white streaks or spots that ruin appearance)

Without tempering, chocolate may look dull, grainy, or even greasy. For a brand like Culinext, dedicated to innovation in chocolate production, tempering is the defining factor of product excellence.

Traditional vs. Automated Chocolate Tempering

1. Traditional Tempering Methods

-

Seeding Method: Adding finely chopped chocolate into melted chocolate to control crystallization.

-

Tabling Method: Cooling chocolate on a marble slab and reheating for stability.

Both require skill, patience, and precise temperature control.

2. Automated Continuous Tempering Machines

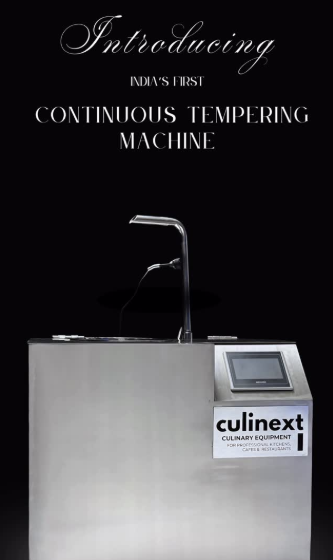

At Culinext, we’ve introduced India’s first continuous tempering machine—a revolutionary step in making tempering effortless.

-

Delivers consistent results at scale.

-

Saves time and reduces manual errors.

-

Ensures every batch has the same glossy, premium finish.

-

Perfect for scaling chocolate production while keeping artisanal quality.

This innovation combines tradition with technology, allowing chocolatiers to focus more on creativity than manual control.

Tips for Perfect Chocolate Tempering

-

Use High-Quality Chocolate – Always start with couverture chocolate for best results.

-

Monitor Temperatures Closely – Each chocolate type has unique tempering ranges:

-

Dark: 45°C → 27°C → 31°C

-

Milk: 45°C → 27°C → 29°C

-

White: 40°C → 26°C → 28°C

-

-

Avoid Moisture – Even a drop of water can ruin the batch.

-

Work in a Cool Room – Ideal temperature: 18–20°C with low humidity.

-

Leverage Technology – If scaling production, switch to an automated tempering machine for efficiency and accuracy.

Why Culinext is the Future of Chocolate Tempering

Culinext is not just a brand—it’s a movement toward automation and efficiency in chocolate production. Our continuous tempering machine is designed to empower chocolatiers, bakeries, and food entrepreneurs to meet modern demand without compromising on quality.

With our innovations, you can master chocolate tempering effortlessly and consistently deliver chocolates that stand out in look, taste, and texture.

Conclusion

Mastering chocolate tempering is the secret to creating premium chocolate products that captivate customers. Whether you are using traditional methods or adopting automation with Culinext’s continuous tempering machine, the key lies in precision, passion, and consistency.

At Culinext, we help you bring your chocolate visions to life with innovation, quality, and excellence.

Related Posts

Popular Tags

Related Posts

Quick Links

Contact Information:

- Aruvi Mobility, Opposite Palakkad ITI West, Kanjikode, Palakkad, Kerala 678623

- +91 70344 40000, +91 73566 79416

- deepak@culinext.co, rithwik@culinext.co

- Monday to Saturday – 9:00 AM to 5:00 PM Closed on Sundays

- Privacy Policy

- Terms of Service